|

|

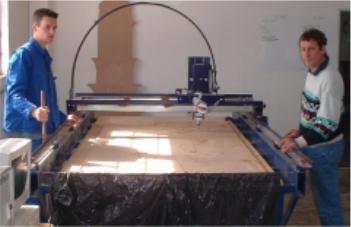

Plywood panel being cut by CNC router. On the left is Sean Dorrington of Mechtronics, on the right is Roy McBride of CKD Boats. Mechtronics is now named CAM Craft

|

|

|

Intermediate drawing from the CNC company showing the plywood components assembled. (Courtesy of Mechtronics)

|

|

|

Didi Mini kits being packed for shipment to USA. They are crated and securely packed to protect them from damage or loss of components.

|

|

|

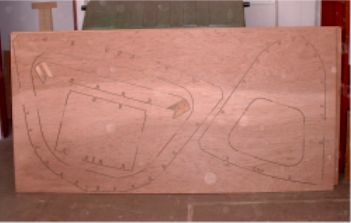

Plywood sheet as supplied by the CNC company. Bulkhead components are held by tabs that are cut by the builder. Bulkheads are broken into smaller components and nested onto the sheets for most effective material use. Accurate stepped scarphs for joining the components are pre-cut by router as part of the process, ready for the builder to quickly assemble. They are supplied in this full-sheet form for simpler packaging for transport and reduced chance of components going missing.

|

|

|

Detail of stepped scarph on component still in plywood sheet. The scarph and the holes for the locating dowels are accurately cut by CNC router. The use of a router, doing multiple depth cuts, allows this detail to be used. This would not be possible with laser or waterjet.

|

|

|

Roy cutting through the tabs that locate the components in the sheet.

|

|

|

Cleaning the edges by sander, or it can be done by hand sanding. This is the centre section of the main bulkhead, at the mast.

|