|

|

Daggerboard and rudder kits. The blanks are laminated timber with the plan and foil shapes cut by CNC router. They are held in the blanks by tabs to protect them during shipping.

|

|

|

The rudders have been cut from the blanks. They are being sprayed with a coat of black paint to assist with final shaping.

|

|

|

Rudder during initial rough shaping with a power plane. The black paint in the pre-cut foil grooves provides a contrast to make it easier to see when the correct depth is reached.

|

|

|

The daggerboard has been shaped as far as possible with a power plane. The black grooves can still be clearly seen.

|

|

|

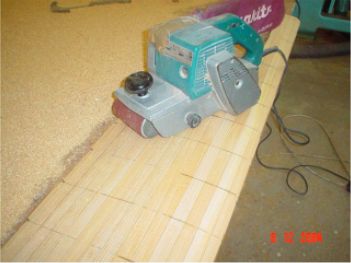

The next stage is to shape down to the final lines with a belt sander. At that stage there will be traces of the black grooves visible but you will not feel them.

|

|

|

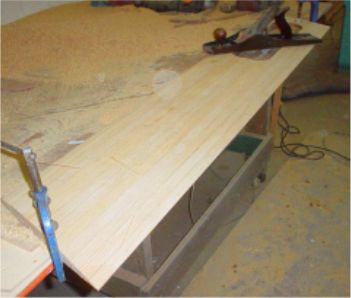

The final phase is to run over the surface with a very sharp hand plane set very fine. This will remove any slight undulations left after belt sanding.

|

|

|

Glassing the daggerboard.

|

|

|

Rudders after glassing and sanding, during painting

|

|

|

Completed rudders.

|