|

Page 7 - Radius skin

|

|

Most of first layer of radius skin dry-fitted. This is being done in 150mm wide strips over most of the hull length and 100mm wide strips for the hollow sections in the bow. Slightly wider strips will also work, probably up to 200mm for most of the radius, but the bow should be kept at 100mm to cope with the complex surface with convex curve in one direction and concave curve in the other.

The joints between the strips of this layer must not be epoxied. They must be free to move during fitting of the 2nd layer, for maximum fairness.

|

|

|

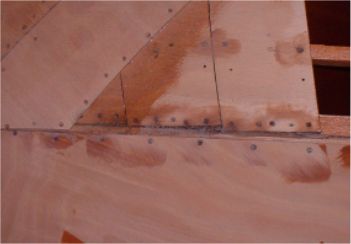

This photo shows both layers of the radius partially completed. The rebate in the edge of the side sheet can be seen, which allows the outer layer of the radius skin to overlap it. Roy has chosen to do the inner layer at 90 degrees to the tangents and the outer layer at 45 degrees. It is not important to do it this way, they can be oriented 45 degrees in opposite directions or both layers oriented the same way and overlapping by half the strip width.

One edge of each strip should be slightly spiled with a hand plane so that it lies tight against the previous strip.

|

|

|

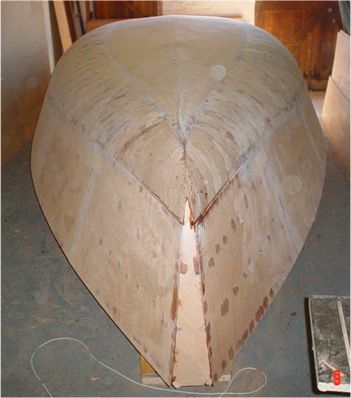

Both layers of the radius completed.

|

|

|